Research Overview

Electrochemical devices — from lithium-ion batteries to protonic ceramic fuel cells — are central to enabling clean energy technologies. Their performance and lifetime depend critically on the coupling between electrochemical reactions, material transport, mechanics, and microstructure.

Our group develops finite-element–based electro-chemo-mechanical models to understand these interactions across scales, from active particles to full devices.

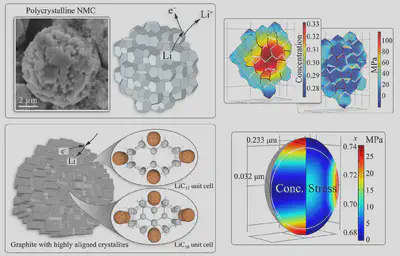

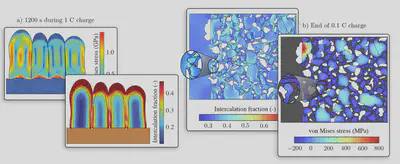

1. Chemo-Mechanical Modeling of Electrode Materials

We create FEM formulations that capture diffusion-induced stress, anisotropic deformation, and phase-transformation mechanisms in electrode materials such as:

- Polycrystalline NMC cathodes

- Highly anisotropic electrodes

- Single-crystal and polycrystalline electrodes

- Silicon anodes with extreme volumetric expansion

These models resolve transport, mechanics, and interfacial behavior simultaneously, enabling prediction of:

- Stress localization

- Grain-boundary failure

- Crack initiation and propagation

- Degradation mechanisms under fast charging

- Influence of particle geometry and anisotropy

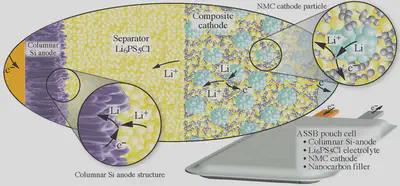

2. All-Solid-State Batteries

A major research direction focuses on all-solid-state lithium batteries (ASSBs), where solid–solid interfaces introduce fundamentally different deformation and degradation pathways.

Our models incorporate:

- Argyrodite (Li₆PS₅Cl) solid electrolytes

- Polycrystalline NMC cathodes

- 3D microstructures from tomography

- Columnar silicon anodes

- Interfacial mechanics and decohesion

- Fabrication pressure and residual stresses

We simulate:

- Stress evolution during cycling

- Interfacial delamination

- Lithium transport in heterogeneous microstructures

- Particle-scale fracture

- Influence of microstructure on lifetime

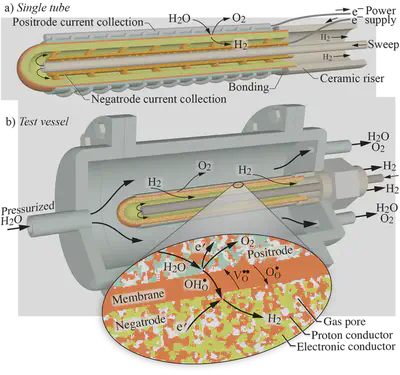

3. Protonic Ceramic Membranes & Electrolyzer Materials

Our group also analyzes protonic ceramics and high-temperature membrane materials, focusing on:

- Coupled thermal–chemical–mechanical behavior

- Stress generation during hydration/dehydration

- Interaction between grain boundaries and proton diffusion

- Failure prediction under long-term cycling

These models unify transport of protons, oxygen vacancies, and species diffusion with nonlinear mechanics.

4. Future Directions

We are expanding our work toward:

- Fracture in sodium-ion and multivalent batteries

- Fabrication-informed models with residual stresses

- Phase-field fracture in solid electrolytes

- High-fidelity, tomography-informed 3D microstructures

- Multiphysics models of electrolyzers and hydrogen devices

- Computationally scalable solvers for large-deformation chemo-mechanics

5. Impact

Our methods support materials discovery and device optimization in:

- Energy storage (Li-ion, Na-ion, ASSB)

- Fuel cells and electrolyzers

- Hydrogen compression technologies

- Membrane reactors

- Solid oxide devices

The resulting frameworks guide industry and national-lab partners in improving durability, energy density, and safety.

This multidisciplinary environment enhances our ability to tackle complex challenges in electrochemical systems modeling.